Home > News

> News Information

Home > News

> News Information

The metal stamping parts processed in the metal stamping workshop are an important component of automobile production. Stamping process is the first of the four major processes in automobile production, and the production of the body, painting, and final assembly workshops is directly influenced by the stamping processing workshop. But the stamping workshop is different from other process workshops. The stamping workshop has the characteristics of high process level requirements, large process complexity, large investment scale, multiple production equipment, and long manufacturing cycle. Some characteristics of the stamping workshop are as follows:

1. Layout of stamping workshop production line

The stamping workshop arranges corresponding production lines based on the overall production capacity of the factory. Due to the different stamping parts required for the product, the number of processes required for metal stamping parts also varies, and each stamping line is generally composed of stamping machines. Stamping lines can be divided into stamping lines of different tonnages based on the production process of metal stamping parts. Generally, each production line needs to produce different metal stamping parts according to the tonnage of the punch press, and these metal stamping parts must be suitable for production on this production line. Due to the production of several different types of processes on each stamping production line, the required punch tonnage for each process is different, so different tonnage punch presses need to be allocated on each production line. For example, the first deep drawing process of metal stamping parts requires a punch press with a relatively large tonnage, while processes such as flanging and punching require punch presses with a relatively small tonnage. Therefore, generally speaking, there will be two relatively large tonnage punch presses on a production line for deep drawing and other work, while other processes require several relatively small tonnage punch presses. This can not only meet the process requirements of production and processing, but also fully utilize equipment resources and reduce unnecessary waste.

2. The process of metal stamping parts is complex

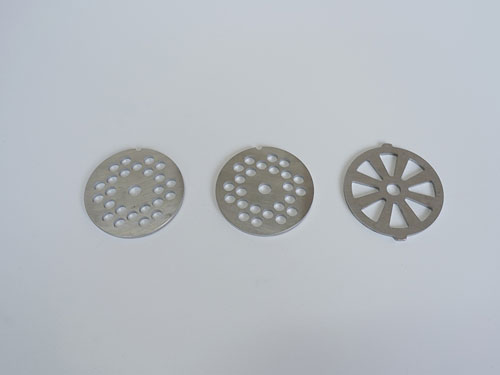

All kinds of metal stamping parts required by the workshop, except for some semi-finished products purchased, are produced by the stamping workshop. The production of each metal stamping part generally goes through several processes, including unwinding, cutting, stretching, forming, trimming, punching, and flanging. Among them, uncoiling and dropping refers to placing the sheet metal on the dropping machine before stamping production, and processing it into a geometric shape suitable for stamping production. Different stamping parts require different production processes, and different production processes require the replacement of different molds for processing. Due to the fixed production process route for each metal stamping part, the complex process route for producing metal stamping parts makes it difficult to arrange production.

3. Production line running simultaneously at both ends

According to the production process requirements of the stamping line, when arranging punching machines of different tonnages for each process, the layout is generally arranged in the order of high, medium, and low tonnages from both ends to the middle. In this way, bidirectional production can greatly improve the production efficiency of the stamping workshop and the utilization rate of the punching machine, thereby reducing production costs. A huge waste of cost.

4. Batch rotation production

When producing metal stamping parts in the stamping workshop, it is not about producing only one product at a time, nor is it about completing all the stamping parts planned for this cycle at once. Instead, it is about taking turns in mass production based on production time, sheet cutting volume, and production economy. Rotating batch production refers to dividing the metal stamping parts scheduled for production within the production plan cycle into several batches according to the needs of the vehicle body workshop. Each batch can produce up to one batch per day, and the final quantity within the planned cycle is completed. The advantage of rotating batch production is that the production time of a single batch of metal stamping parts will not be too long, which will affect the production of other metal stamping parts, leading to the use of downstream workshops and reducing production costs.

5. Changes in production batch constraints

The production plan of the stamping workshop is determined by the type, quantity, and inventory of stamping parts required by the body workshop. However, there are many uncertain factors in the production process of metal stamping parts, such as raw material shortages, changes in demand in the body workshop, punch presses, mold failures, etc., which cause changes in the production batch. However, considering that the production batch is too small, it will increase the number of mold changes, while the production batch is too large, which will increase production costs, it is necessary to determine a more reasonable range of production batch changes.

.jpg)