Home > News

> News Information

Home > News

> News Information

1. Generally speaking, edge cutting, punching guidance, pre cutting, wire pressing, wire collision, tearing (cutting, stretching) are carried out first, followed by punching and cutting, edge pressing, forming, and bending in two steps. One half is formed first, and then the other half is formed.

2. When punching and dropping materials, it is generally recommended to punch small holes first and then large holes; Firstly, stamping the waste around the edge of the formed material, and then dropping the excess material from other parts; If the punching hole is placed at the back, there may be gaps around the punch during the punching process (front punching). In this way, uneven force (lateral force) will be generated during the stamping process, and the punch strength of the small hole is weak, making it easy to break. Of course, this is only the majority, and small holes can only be arranged at the back, but there is still a way. If the thickness of the punch is too small, it can be reinforced online. A: Adopting precise guidance for detachment from the board; B: The punch is processed using PG (optical grinding).

3. Determine whether to use trimming:

Edge cutting is generally used on continuous molds and feeding molds to provide rough positioning and facilitate feeding during mold testing; Some edge cutting also has the function of stamping shape. If the mold first punches the positioning pinhole and then immediately guides it with a guide needle, edge cutting is generally not required; If there is no guide needle, it is necessary to cut the edge and set the distance, which is generally used in the blanking die.

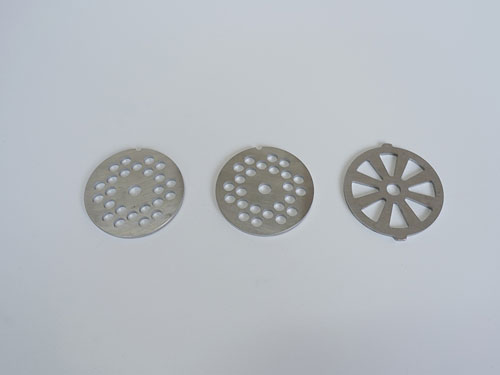

There are several punch shapes used for edge cutting:

a: Punching machines are commonly used for punching dies and thick material edge cutting, with low positioning accuracy. Its length=step distance, as long as the punch strength is ensured, the width can be 3.0~6.0.

b: This type of punch has a 3/4 arc (R is usually 0.3~0.6) at the head, with a length<=step distance, to prevent edge cutting waste from getting stuck inside and prevent chip jumping. It is commonly used for punching thin high-speed molds.

c: This type of punch, like B, is a variant of it. It uses a V-shaped clamp to hold the cutting edge waste to prevent flipping and chip jumping, with an angle of 50 °~70 °.

d: This type of punch not only cuts the edges but also takes on the shape.

The purpose of this step head is to provide guidance and reduce lateral forces.

4. Pre cut, about to be cut off, but not yet cut off (usually placed in front of the workstation)

Due to the electroplating requirements of hardware and electronic products, for the convenience of electroplating, the small products punched out will not directly fall off, but remain on the pre cut material strip. After electroplating, it can be folded twice by hand or mechanically to remove. Pre cut: It needs to be cut on both sides, with a depth of 4/1 of the material thickness on each side. Simply fold it twice (up and down) to remove the product; The width of the pre cut punch and the punch head should be 0.02~0.05, the angle should be 50 °~70 °, and the length should be 0.2~0.5 greater than the length of the pre cut line on each side.

Description: In order to facilitate processing, material preparation, and mold calibration, the thickness of each template in each factory is generally standardized and specified (except in special circumstances). In the continuous mold, due to the form of the material strip, in order to control the pre pressing amount of the material strip and the balance of the template, a material strip groove is often ground in the middle of the stripping plate: the depth of the groove=material thickness -0.03~0.05 (that is to say, the pre pressing amount is 3~5 strips), and the width of the groove is 2~4 millimeters larger than the width of the material strip. Therefore, the thickness of the stripping plate often varies with the thickness of the material, and its size=the specified thickness of the stripping plate material thickness -0.03~0.05. However, in engineering molds, it is generally not necessary to grind the product groove: because the products of engineering molds are generally larger, not as narrow and slender as continuous mold material strips, which means that the thickness of the stripping plate of engineering molds is generally unchanged.

5. Determine the size and position of the correct hole

General continuous molds require punching and alignment for precise positioning and post-processing. In engineering molds, the inner holes or shapes of commonly used product parts are used to achieve the positioning of the next process. If there are neither inner holes nor shapes available for positioning, only process holes can be used. For example, in the first project, convex cells are punched, while in the second project, the shape is removed. In the first project, two process holes must be drilled simultaneously at the opposite corners of the shape (the size of the hole is related to the material thickness: commonly 3.0-6.0) for the positioning of the next process and the knowledge of high-speed stamping die design.

.jpg)