Home > News

> News Information

Home > News

> News Information

In the vast world of kitchen appliances, the cutting and slicing knife disc has become an indispensable member of modern kitchens with its efficient and precise cutting ability. It not only quickly transforms ingredients into uniform and delicate filaments or flakes, but also plays an important role in improving cooking efficiency and dish aesthetics. This article will delve into the manufacturing process details of the slicing knife disc, analyzing the birth process of this kitchen tool from material selection, design principles, production and processing to quality inspection.

Material selection: the cornerstone of durability and safety

The core of the slicing disc lies in the material of its blade and disc. Firstly, blades are typically made of high carbon stainless steel or ceramic materials. High carbon stainless steel, due to its excellent hardness, wear resistance, and corrosion resistance, can ensure that it remains sharp even after long-term use, while also being easy to clean and maintain. Ceramic blades, on the other hand, are an ideal choice for handling sensitive ingredients (such as vegetables) due to their extremely high hardness and non stick properties. Although the cost is high, they have a long service life and a more delicate cutting effect.

The cutting disc substrate is often made of aluminum alloy or food grade plastic material. Aluminum alloy, due to its good heat dissipation performance and structural strength, can effectively resist the impact and deformation during the cutting process; Food grade plastics, with their lightweight, corrosion-resistant, and easy to shape characteristics, have become the preferred choice for users who pursue lightness and convenience.

Design principle: The art of precise cutting

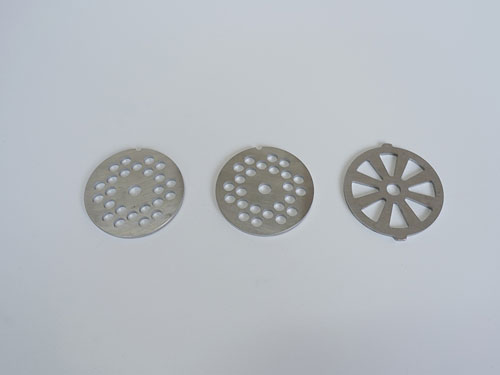

The exquisite design of the cutting disc lies in its blade arrangement and disc structure. Blades are usually arranged in a spiral or staggered pattern to ensure that ingredients can be evenly and continuously cut as they pass through. This design not only improves cutting efficiency, but also avoids the waste and damage of ingredients. At the same time, the aperture size, shape, and distribution of the cutting disc have been carefully designed to accommodate different types and sizes of ingredients, achieving precise cutting.

In addition, some high-end knife discs also incorporate the function of adjustable blade spacing, allowing users to adjust the cutting thickness according to their needs, achieving free switching from fine threads to thick slices, and meeting diverse cooking needs.

Production and processing: showcasing fine craftsmanship

The production and processing of wire cutting and slicing cutters is a complex process that integrates precision machining, surface treatment, assembly and debugging. Firstly, high-precision CNC machine tools are used to perform preliminary processing such as cutting, stamping, and drilling on raw materials, forming the basic shapes of blades and cutterheads. Subsequently, laser welding or precision bolt fixation are used to firmly install the blade on the cutterhead substrate, ensuring stability and safety during the cutting process.

In the surface treatment process, both the blade and the disc need to undergo processes such as grinding, polishing, and rust prevention to enhance their appearance, texture, and service life. Especially for stainless steel blades, passivation treatment is required to reduce their surface activity and enhance their corrosion resistance.

Quality Inspection: The Key to Quality Assurance

Every cutting and slicing disc must undergo strict quality inspection before leaving the factory. This includes but is not limited to blade sharpness testing, cutting efficiency evaluation, durability testing, and safety checks. By simulating actual usage scenarios, a comprehensive evaluation of the cutting effect, noise level, and ease of cleaning of the cutterhead is conducted to ensure that the product meets relevant standards and user expectations.

In addition, some manufacturers also conduct random sampling of finished products and send them to third-party testing institutions for more comprehensive performance testing to further verify product quality.

As a powerful assistant in modern kitchens, the cutting and slicing disc embodies the wisdom and sweat of craftsmen in every detail of its manufacturing process. From the selection of high-quality materials, to the application of exquisite design, to the implementation of fine craftsmanship, and strict quality inspection, every link is indispensable, jointly creating the excellent quality of this kitchen weapon. With the advancement of technology and the continuous improvement of consumer demand, we have reason to believe that the cutting and slicing disc of the future will be more intelligent, efficient, and user-friendly, bringing more convenience and surprises to our lives.

.jpg)