Home > News

> News Information

Home > News

> News Information

1、 Classification of stamping dies

According to the structure, stamping molds can be divided into three categories: single engineering molds, composite molds, and continuous molds. The first two types require more manpower and are not economically efficient. Continuous molds can efficiently produce in bulk. Similarly, when designing a set of high-speed precision continuous stamping molds, you should also pay attention to the products you produce (including all stamped products). In order to achieve the goal of automated batch production of continuous stamping dies, attention should be paid to issues such as spacing between modules, machining accuracy of parts, assembly accuracy, matching accuracy, and interference.

2、 Concept of Unit Design

The overall structure of stamping molds can be divided into two parts: (1) common parts; (2) The parts that vary depending on the product. Common parts can be standardized or normalized, while parts that vary depending on the product are difficult to standardize.

3、 Composition and specification of formwork

1. Composition of templates

According to the type, composition, and differences of molds, stamping molds can be divided into two categories: configuration type structures and reverse configuration type structures. The former is the most commonly used structure, while the latter is mainly used for stretch forming molds or matching with special molds.

The main tasks include:

(1) Digital drafting - converting 3D product and mold models into 2D engineering drawings used in conventional machining;

(2) Digital design of molds - based on product models and design intentions, establish corresponding 3D solid models of molds;

(3) Digital analysis and simulation of molds - based on the forming process conditions of the product, perform structural analysis, thermal analysis, fatigue analysis, and motion analysis on mold parts;

(4) Product molding process simulation - injection molding, stamping molding;

(5) Customize standard parts and standard design processes suitable for the company's mold design;

(6) Mold production management.

2. Mold specifications

(1) Mold size and locking screws

The template size should be larger than the work area, and standard template sizes should be selected. The position of the template locking screw is related to the type of mold and the size of the template. Among them, locking screws are most commonly used for the four corners of a single engineering mold, and the most standard working area can be widely used. The most commonly used locking screws for long and continuous molds are arranged at the four corners and middle positions.

(2) Thickness of template

The thickness of the template is absolutely related to the mold structure, stamping processing type, stamping processing force, stamping processing accuracy, etc. It is difficult to determine the thickness of the mold based on theoretical calculations, and it is generally obtained from experience. The types of template thickness used in the design should be minimized, and the height and clamping height of the mold should be standardized to ensure its structure and inventory management.

4、 Template design

The main templates of continuous molds include punch fixing plates, pressing plates, mother templates, etc. Their structural design depends on the accuracy of the stamped product, production quantity, processing equipment and methods, and maintenance methods of the mold. There are three forms: (1) integral; (2) Yoke type; (3) Inlaid style.

1. Integrated style

The integral template, also known as the integrated construction type, must have a closed processing shape. The integral template is mainly used for molds with simple structure or low precision. Its processing method is mainly cutting processing (without heat treatment). The template that has undergone heat treatment must be processed by wire cutting, discharge machining, and grinding. The on-site platform with long template size (continuous template) will use two or more pieces as a whole.

2. Yoke style

The central part of the yoke template is processed into a groove shape to assemble into block products. According to application requirements, the groove can be formed by other templates. The advantages of this yoke type template structure include easy groove processing, adjustable groove width, and good processing accuracy, but rigidity is its disadvantage.

The design considerations for yoke templates are as follows:

(1) The fit between the yoke plate structure and the block components adopts intermediate fit or light fit. If strong press fit is used, the yoke plate will change.

(2) The yoke plate has the retention function of block shaped components and must have sufficient rigidity to withstand the lateral and surface pressure of the block shaped components. In addition, in order to ensure a tight fit between the yoke groove and the block shaped part, the corners of the groove are processed with escape clearance. If the corners of the yoke groove cannot be processed with escape clearance, the block part must be processed with escape clearance.

(3) The segmentation of block shaped parts should also consider the internal shape, and the reference plane must be clear. To avoid deformation during stamping, attention should also be paid to the shape of each block part.

(4) When assembling the yoke plate with multiple block components, the pitch changes due to the accumulated processing errors of each block component. The solution is to design the middle block part in an adjustable manner.

(5) The mold structure of block shaped parts is assembled side by side, because block shaped parts will bear lateral pressure during stamping processing, resulting in gaps between block shaped parts or tilting of block shaped parts. This phenomenon is an important cause of poor stamping dimensions and chip blockage, therefore, sufficient measures must be taken.

(6) There are five ways to fix the block shaped components in the yoke plate according to their size and shape:

A、 Secure with locking screws; B、 Fixed with keys; C、 With? Shape key fixation; D、 Secure with shoulders; E、 Press firmly to fix the upper part (such as the guide plate).

3. Inlaid style

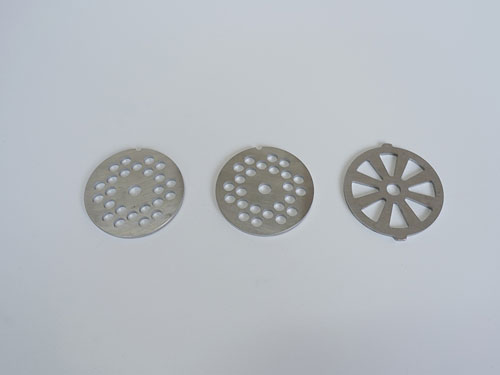

Circular or square concave parts are processed inside the template, and block shaped components are embedded inside the template. This template is called an embedded structure, which has a small cumulative tolerance and high rigidity during processing, and has good accuracy reproducibility during disassembly and assembly. Due to its advantages of easy mechanical processing, processing accuracy determined by the working machinery, and minimal engineering adjustments, the embedded template structure has become the mainstream of precision stamping molds. However, its disadvantage is the need for high-precision hole machining machines. When the continuous stamping die adopts this template structure, an empty station is designed to meet the high rigidity requirements of the template.

The precautions for constructing embedded templates are as follows:

(1) Processing of embedded holes: Vertical milling machines (or fixture milling machines), comprehensive processing machines, fixture boring machines, fixture grinding machines, wire cutting discharge machining machines, etc. are used for template embedded hole processing. For the machining standard of embedded holes, in order to improve the machining accuracy when using wire cutting discharge machining machines, two or more wire cutting processes need to be performed.

(2) The fixing method of embedded parts: The decisive factors of the fixing method of embedded parts are not changing the machining accuracy, the ease of assembly and disassembly, and the possibility of adjustment. There are four methods for fixing embedded parts: A. fixing with screws; B. Secure with shoulders; C. Fix with toe blocks; D. Press the upper part tightly with sheet metal. The fixing method of the mother template insert block also adopts press fit fitting. At this time, relaxation results caused by processing thermal expansion should be avoided. When using circular mold sleeve inserts to process irregular holes, anti rotation methods should be designed.

(3) Considerations for disassembly and assembly of embedded parts: The machining accuracy of embedded parts and their holes is required to be high, which facilitates assembly operations. In order to achieve adjustments during assembly even with small dimensional errors and to consider solutions in advance, the following five specific factors should be considered when processing embedded parts: A. Setting up the press in inlet part; B. Adjust the pressing state and correct position of the embedded part with a spacer; C. Set up extrusion holes on the bottom surface of the embedded part; D. Directly use screws of the same size for locking and loosening; E. In order to prevent errors in assembly direction, anti mistake chamfering should be designed.

.jpg)